HDPE Water Supply Pipe Fittings

1. Standard: ISO4427-2007

2. Injection Mould Pipe Fittings.

3. The types and specification of injection mould pipe fittings produced by us are complete.

4. Adopting inward PE or PE100 high quality material for production.

5. The working pressure meets the requirements of the pipe network pressure.

6. The inner wall is smooth and the resistance is low.

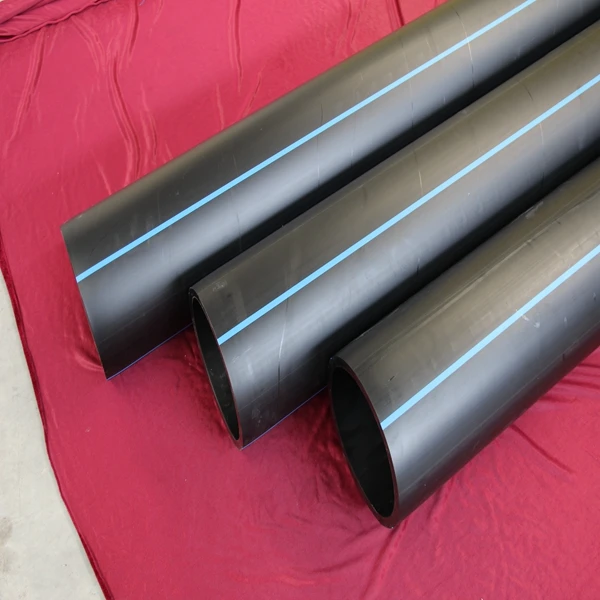

HDPE WATER PIPE

Overview

The polyethylene water supply pipe is a new product formed from extruding, taking the high quality polyethylene resin as main material, adding necessary assistant such as anti-oxidant ultraviolet absorber and so on. The polyethylene water supply pipe has application history of forty years abroad. It is perfect choice in many pipelines by the approving of practice. It can be widely used in many kinds of pipeline projects with the working pressure of 0.32MPa~1.6MPa and the working temperature of -20℃~40℃, such as municipal water supply, drainage, petrochemical industry, mine, irrigation of agricultural land, contamination drainage, mortar transportation, landfill of refuse and so on.

Advantages of HDPE Pipes

1. Excellent physical characteristics

The inward high quality polyethylene has good rigidity and intensity, and also has good suppleness and anti-creep, and the hot melting performance is good, which is convenient for the mounting of the plastic pipelines.

2. Corrosion resistant, long lifespan

In the coastal areas, the ground water lever is higher, the ground humidity is great, the seamless steel pipes must be used to prevent corrosion, and the lifespan of the steel pipes is only 30 years. While the HDPE pipes can proof many chemical mediators which cause the corrosion without needing the corrosion proof treatment. In addition, it will not improve the alga, bacteria or epiphyte growing. The lifespan can reach up to 50 years under the normal condition.

3. Good toughness and suppleness

HDPE pipe is high toughness tubing, the breaking extension exceeds 500%. It has very strong adaptability to the dropping with uneven base and dislocation, good shock resistance. It has been proved by practice all over the world that the HDPE pipes are the pipelines with excellent shock resistance. In addition, the suppleness of the HDPE pipes can make them coiled up easily at a small diameter, which decrease a lot of connection pipe fittings. In construction, the allowable bending radius of the pipes can bypass obstacles, which can decrease the construction difficulties.

4. Great negotiability and economical

The inner wall of the HDPE pipes is very smooth. The equivalent absolute rough radio of the inner wall is 1/20 of the steel. The price of the HDPE pipes under the same pipe diameter, length and pressure is about 30% of the steel pipes.

5. Convenient for connection, easy to construct

The HDPE pipe is very light. It is convenient for transportation and easy to weld. The weld-throat section is few.

6. Good sealing performance

The HDPE pipe adopts the hot melting connection which guarantees the identity of the joint material structure and pipe body and realizes the integration of the joints and the tubing. The tensile and burst strength are both higher than the pipe body, which effectively resist the ring stress from the inner pressure.

7. Good stress resistant performance

The HDPE pipe has low gap sensitivity, high shear strength, excellent scar resistant ability and outstanding environment resistance stress.

8. Low temperature shock resistance

The brittle temperature of the polyethylene is very low which can be used in the temperature range between -20℃~ 40℃.

9. Good abrasion resistance

It can be shown in the abrasion resistance performance test of the polyethylene pipes and steel pipes. The abrasion resistance of the HDPE pipe is 4 times of the steel pipe.

10. Low flow resistance

The inner wall of HDPE pipe is very smooth. The smooth wall and non-adherence performance can guarantee the flow capacity of the HDPE pipes. At the same time, this will decrease the pressure loss and energy consumption of the water flow.

Application Area

1. Town Water Supply

With integrative advantages of safe, health and continent for construction, the HDPE pipeline has been the perfect tubing for the town water supply.

2. Food, Chemical Industry Area

With the unique chemical corrosion performance, the HDPE pipe can be used in the transportation and emission of many acid, alkali and salt solutions. The working life is long, the cost and maintenance discharge is low.

3. Argillaceous Silt, Mud Transportation

The abrasion resistance of the PE pipelines is four times of steel pipes, so it can be used to transport the argillaceous silt, pulverized fuel ash of the power plant, mud accumulated in the river way.

4. Replace the Cement Pipes, Cast Iron Pipes and Steel Pipes

To reform the cement pipes, cast iron pipes and so on laying previously. Without digging in large area, the PE pipes can be inserted into the old pipes for replacing at low construction cost and short construction time. It is suitable for the reformation of the old city especially.

5. Garden Green Pipe Network

The garden green needs lots of the water transportation pipelines, as the cost of the PE pipelines is very low, it is worthy to be improved widely.

Physical and Chemical Property of HDPE Pipes

|

Item |

Requirement |

|

|

At break elongation (%) |

≥350 |

|

|

Vertical shrinkage rate (100℃,%) |

≤3 |

|

|

Oxidation time (200℃,min) |

≥20 |

|

|

Weatherability (the accumulative aging of 3.5GJ/m2) |

80℃ hydrostatic strength 165h |

No breakage and leakage |

|

Breaking elongation (%) |

≥350 |

|

|

Oxidation time (200℃,min) |

≥10 |

|

Performance Requirement

|

Item |

Pressure |

Requirement |

|

|

PE80 |

PE100 |

||

|

20℃ hydrostatic strength (100h) |

9.4 |

12.4 |

No breakage and leakage |

|

80℃ hydrostatic strength (165h) |

4.6 |

5.5 |

No breakage and leakage |

|

80℃ hydrostatic strength (1000h) |

4.0 |

5.0 |

No breakage and leakage |

Pipe Connection

The ways of connecting HDPE pipes can be divided into electro-fusion and butt fusion.

The general principle of HDPE pipe welding is that the polyethylene is melting from 190℃ to 240℃, then if the melt pipes can be fully connected with proper pressure after cooling. HDPE pipes can be connected with other material of pipes and parts, such as cast iron pipes, valves and fittings etc through proper use of flanges or HDPE/steel transition connecting fittings.

About us:

Company Information

1. Long History

Shandong Yost Import And Export Co., Ltdwas founded in 2003. The company relies on Shandong Yost Group Co., Ltd, which has several factories, and mainly engaged in the foreign water conservancy engineering machinery and equipment, spare parts of overseas investment and export, technology consulting and construction services business.

2. Convenient Location

Shandong Yost Group is located in Jinan, which is very famous for its beautiful and magnificent spring in China.

3. Major products

We has been engaged in collection of plastic pipe fittings, water meter, industrial valves and other water conservancy engineering equipment technology research and development, production and processing,sales and technical service for fifteen years.

4. Strong Backing

The parent company owns six plastic pipe production bases which produce PVC-U pipes, HDPE pipes, PVC-M pipes, PPR pipes and plastic pipe fittings.And Shandong Yost Group also owns a large industrial valve production branch.

5. Advanced Technology

Scientific management and advanced technology make all our products pass the ISO9001 quality management system certification and ISO14001 environmental management system certification.

Our Services:

Pre-sales

* Prompt reply .

* Reasonable price.

*Free sample available.

*customers designs and logo are welcome

After-sales

*On time delivery.

*Care about cautomer what products to use.

*Updated new product and price let you know.

*Product warranty time must be ensure.

FAQ

*Are you a factory or a trading company?

Factory.Our factory specialized in pipes for 10 years in China ,not only target foreign market,we also offer products in domestic market.

*What’s the main products of your company?

We mainly produce HDPE/PVC/PPR/CPVC/MPP pipe,double wall corrugated pipe and pipe fittings.They can be use for electrical,drainage,water supply,gas supply.

*Which countries did your company ever export before?

Our product have exported to Nigeria,Fiji,Kenya,South Africa,Saudi Arabia,Zambia,France,Tanzania, Canada, Palau, India,Singapore, Belgium,Mongolia,Australia......

*How many years the products guarantee?

About 50 years.We offer the installation way for you after selling if you need.

* How can I get Samples?

We are glad to offer free sample for you by air transport,but shipping fee needs buyer to pay it.

*What is your payment terms?

We accept 30% T/T down payment ,70 %T/T before delivery.

*What is the certificate of your products?

*We have ISO and CE standard,we also support third party testing products before export.For example,SGS.

*What is the advantage of your products?

Production time fast,easy to install,wide range of uses,long service life.

*Whether the pipe price can be more discount?

If the quantity of order more big,then we will give you more discount.