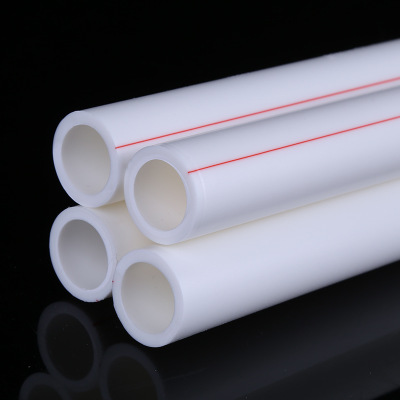

PPR PIPE

Features:

1. Hygienic, non-toxic, non-corrosive, never fouling;

2. High temperature resistance (maximum conveying water temperature up to 95 °C), high pressure resistance (pressure test strength up to 5 MPa or more);

3. Using hot-melt connection, the pipe and pipe fittings are homogenized and melted into one body, which is safe and reliable and never leaks;

4. The thermal conductivity is low, the thermal conductivity of the PP-R tube is 0.21w/mk (only one-twoth of the metal tube), and the thermal insulation performance is good;

5. Light weight, convenient to carry and low construction strength;

6. The inner wall of the pipe is smooth, the pressure loss is small, and the water flow speed is fast;

7. Pipeline transmission noise is small, noise is reduced by 40% (compared with galvanized pipe);

8. The color of the product is soft and beautiful, and it can be installed in the room or in the dark.

9. Good chemical resistance;

10. The installation is simple and fast, and the construction cost is low;

11. Long service life, under normal conditions, the service life can reach more than 50 years.

Specification size and performance parameters:

|

公称外径 |

管材型号 |

|||

|

|

标准尺寸率(管系列)(工程压力PN) |

|||

|

|

S5(1.25mpa) |

S4(1.6mpa) |

S3.2(2.0mpa) |

S2.5(2.5mpa) |

|

(dn mm) |

壁厚C |

壁厚C |

壁厚C |

壁厚C |

|

16 |

- |

2 |

2.2 |

2.7 |

|

20 |

2 |

2.3 |

2.8 |

3.4 |

|

25 |

2.3 |

2.8 |

3.5 |

4.2 |

|

32 |

2.9 |

3.6 |

4.4 |

5.4 |

|

40 |

3.7 |

4.5 |

5.5 |

6.7 |

|

50 |

4.6 |

5.6 |

6.9 |

8.3 |

|

63 |

5.8 |

7.1 |

8.6 |

10.5 |

|

75 |

6.8 |

8.4 |

10.3 |

12.5 |

|

90 |

8.2 |

10.1 |

12.3 |

15 |

|

110 |

10 |

12.3 |

15.1 |

18.3 |

|

160 |

14.6 |

17.9 |

21.9 |

26.6 |

Installation Precautions:

1. The surface to be welded of the pipe and the pipe must be kept clean and free of oil. It is recommended to clean it with 95% alcohol.

2. The welder die must be cleaned with a clean, soft cloth before welding. The welder temperature is set to 260±10°C. If the PPR special welder is used, the lock is 260°C, and only the green light is on. The pipe fittings should be inserted into the die at the same time, and the heating time should be strictly in accordance with the specifications. After being pulled out from the die, the plugging fusion should be completed within the specified melting time.

3. The hot-melt pipe shall not exceed the depth of the drawing line to prevent the overflow of the fuse from excessively blocking the inner hole of the pipe. When the line is drawn, the oil pen shall not be used to prevent the ink from contaminating the surface to be welded.

4. The pipe and pipe fittings shall not be rotated during the insertion, and shall be inserted vertically. After normal welding, there shall be two uniform and clean spills at the joint end face.

5. When welding elbows, tees and valves, pay attention to the direction, and the surface reinforcement of the pipe can be used as a direction reference.

6. The pipeline should be kept away from the heat source. It should not be directly connected to the inlet and outlet of heat sources such as water heaters and water heaters. It should be connected by metal corrugated hose or metal pipe. The length of the transition joint pipe should not be less than 350mm.

7. Pipes laid in direct burial (including in-wall laying and floor covering) shall not be threaded or flanged.

8. When installing pipe fittings such as valves, faucets, etc., it is required to wind several layers of PTFE sealing tape (raw tape) as a sealing medium at the external thread. If disassembly is required, replace the raw tape when reinstalling.

9. When installing the pipe fittings with inserts, use a wrench or manually tighten them. The force should be soft. Excessive tightening of the pipe fittings may cause cracks and water leakage and slippage. Care must be taken not to overtighten.

10. Effective waterproofing measures should be taken at the pipeline crossing level and underground outdoor wall. At the crossing of the load-bearing wall, a hole should be reserved, and the balance of the pipe at the hole should be greater than the settlement of the building.

11. Construction in cold winter areas to avoid pressing, colliding, throwing, and knocking on pipes.

12. Pressure testing must be performed before the dark pipe is buried.

13. If you want to make some adjustments to the welded part, the adjustment angle should not exceed 5°, and it must be adjusted immediately after the welding is completed (the distance from the welder die cannot exceed the fusion time in the hot melt parameter table), otherwise it will result in Defects in the connection.

14. Hot water pipes and cold water pipes should be laid in parallel. When laying horizontally, the hot water pipe should be laid on the outside. When laying up and down, the hot water pipe should be laid on the upper side. When laying vertically, the hot water pipe should be on the left side (the general faucet is left-handed hot water and right-handed cold water when adjusting temperature).

15. The dark wall of the pipe inlay should be matched with the reserved groove of the civil construction. When the size design is not specified, the depth of the wall groove is dn+(20~30)mm and the width is dn+(20~30)mm. When the horizontal groove is long or the groove depth exceeds 1/3 of the wall thickness, the approval of the structural professional should be obtained. The surface of the groove shall be flat, and there shall be no protrusions such as sharp corners. The pipe shall have fixing measures; after the pipe is tested, the corner shall be filled with M10 cement mortar. When the hot water branch pipe is directly buried, the thickness of the M10 mortar layer covered on the surface shall not be less than 20 mm.

About us:

Our service:

Pre-sales

* Prompt reply .

* Reasonable price.

*Free sample available.

*customers designs and logo are welcome

After-sales

*On time delivery.

*Care about cautomer what products to use.

*Updated new product and price let you know.

*Product warranty time must be ensure.

FAQ

*Are you a factory or a trading company?

Factory.Our factory specialized in pipes for 10 years in China ,not only target foreign market,we also offer products in domestic market.

*What’s the main products of your company?

We mainly produce HDPE/PVC/PPR/CPVC/MPP pipe,double wall corrugated pipe and pipe fittings.They can be use for electrical,drainage,water supply,gas supply.

*Which countries did your company ever export before?

Our product have exported to Nigeria,Fiji,Kenya,South Africa,Saudi Arabia,Zambia,France,Tanzania, Canada, Palau, India,Singapore, Belgium,Mongolia,Australia......

*How many years the products guarantee?

About 50 years.We offer the installation way for you after selling if you need.

* How can I get Samples?

We are glad to offer free sample for you by air transport,but shipping fee needs buyer to pay it.

*What is your payment terms?

We accept 30% T/T down payment ,70 %T/T before delivery.

*What is the certificate of your products?

*We have ISO and CE standard,we also support third party testing products before export.For example,SGS.

*What is the advantage of your products?

Production time fast,easy to install,wide range of uses,long service life.

*Whether the pipe price can be more discount?

If the quantity of order more big,then we will give you more discount.